Embedded PWM Driver

For one of my robotics projects I needed to turn an

antenna from side-to-side. So I pulled out my servos, breadboard, 555

timer, assorted gates, resistors, caps, and other crap to start putting

together a driver. I've probably did this dozens of times over the

years. As I was looking through the bins of assorted electronics stuff

I found my box of uContollers. At that point the 'duh' light goes on.

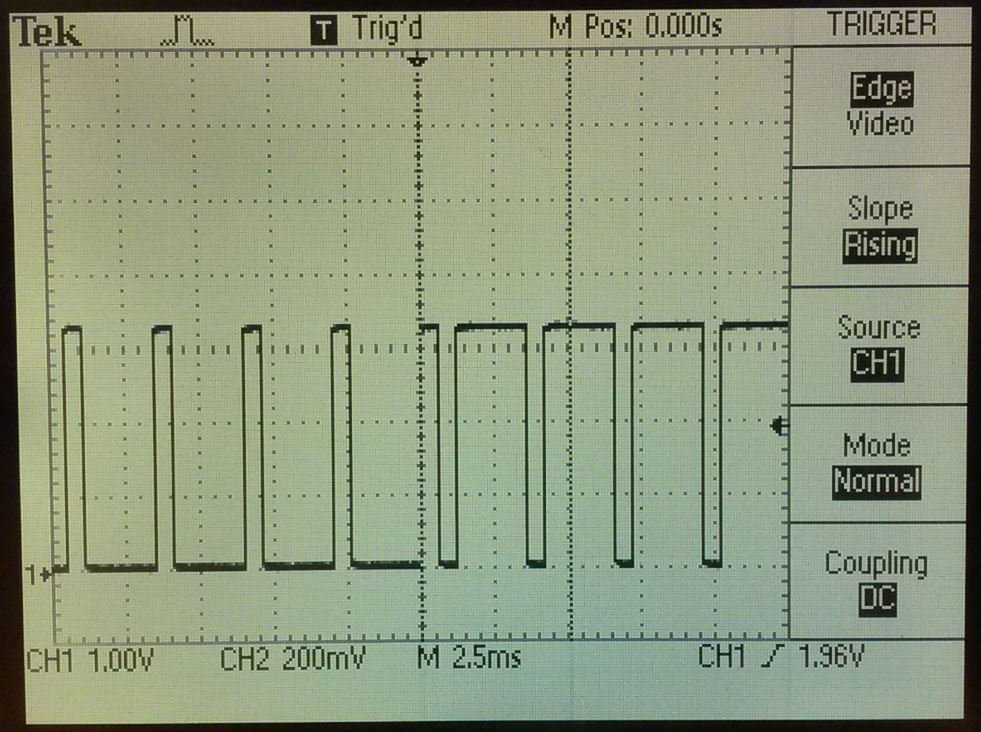

Pulse

Width Modulation (PWM) is a form of signal modulation where the widths or

pulses correspond to specific data values. For servos, the different

pulse widths would correspond to different positions of the servo. The

picture below (right) shows the pulse train going to the servo. The

period (1/freq) is about 3mS or a 333Hz pulse train. This frequency will vary

depending on the servos you are using but most are in the hundreds of Hz

to lower Khz range. There is usually a dead-band at both extremes,

maybe less than 5% and greater than 95%. Here no change will happen.

If a PWM signal with a 50% duty cycle were sent the servo would go to its

180 degree position. A 5% duty cycle may send it to 20 degrees and 95% to

340 degree. The ratios and actual positions depends on the servos.

Pulse

Width Modulation (PWM) is a form of signal modulation where the widths or

pulses correspond to specific data values. For servos, the different

pulse widths would correspond to different positions of the servo. The

picture below (right) shows the pulse train going to the servo. The

period (1/freq) is about 3mS or a 333Hz pulse train. This frequency will vary

depending on the servos you are using but most are in the hundreds of Hz

to lower Khz range. There is usually a dead-band at both extremes,

maybe less than 5% and greater than 95%. Here no change will happen.

If a PWM signal with a 50% duty cycle were sent the servo would go to its

180 degree position. A 5% duty cycle may send it to 20 degrees and 95% to

340 degree. The ratios and actual positions depends on the servos.

The coding of the uController is pretty straight forward. Basically

you need to create a real time delay using the uController on-board crystal

or timer. I set mine up for 1uSec increments. The rest is just

shifting in 1s or 0s into the register which cooresponds to the desired

output pin. The Atmel MEGA-1284P demo board I used just happens to

have an LED wired to the same output register. Code snippet below.

I will note you need to be careful how you write the code. Remember,

the servo will go to and stop at a position but you need to continuously send

the PWM signal. If the pulse train stops like when a delay or

interrupt is sent the servo will slip back if torqued. One of the

simple ways to code is just to know the position-to-position travel time and

add the extra time needed in the loop. The snippet below drives the

servo to a position and allows for it to stay in that position for 1sec.

Why not just use a uController?!?! After all, these are the kinds of

applications they were designed for. Years of conditioning makes you

want to grab wire and a breadboard but here we have a programmable solution

all in one chip.

To begin with, a servo (or servomotor) is an error-sensing, error-correcting

motor. They're a digital / analog hybrid containing a motor and either

a potentiometer for position sensing or an encoder which provides both speed

and positioning using proportional integral derivative (PID). Most

servos have a less than 360 degree rotation (but not always) and are driven

using pulse width modulation (PWM).

Embebbed

PWM Driver

PWM Generator - Source

Code

A lot easier than the breadboard

route.