Modbus

From

the Wiki,

Modbus is

a data communications protocol originally

published by Modicon (now Schneider Electric)

in 1979 for use with its programmable logic

controllers (PLCs).

Modbus has become a de facto standard communication

protocol and is now a commonly available means of connecting industrial electronic devices.

From

the Wiki,

Modbus is

a data communications protocol originally

published by Modicon (now Schneider Electric)

in 1979 for use with its programmable logic

controllers (PLCs).

Modbus has become a de facto standard communication

protocol and is now a commonly available means of connecting industrial electronic devices.

In short, Modbus is a request-response protocol where the client sends a

request to a device, and the device sends a response back to the client.

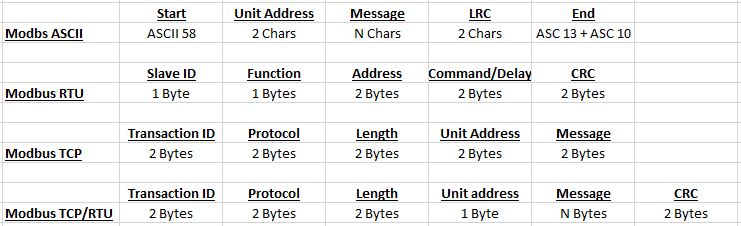

These are just 4 types Modbus protocols:

Modbus ASCII - a serial ASCII protocol

Modbus RTU - an 8 bit serial protocol

Modus TCP - a TCP/IP protocol

Modbus RTU/TCP - TCP/IP protocol w/CRC check

This page will deal mainly with Modbus RTU simply because this is

the stuff I have laying around on the bench.

Modbus Frame Formats

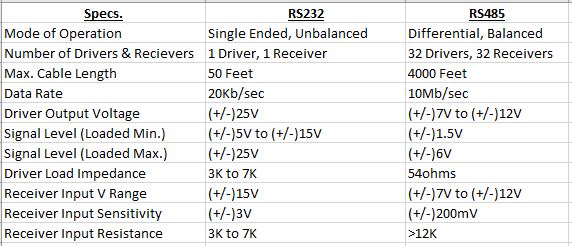

RS232 vs. RS485

Both RS232 and RS485 are standard communication protocols and work with

Modbus. RS422 will also work but over the years it has lost it

popularity. Data is exchanged between sets of data line drivers

and receivers. RS232, the oldest of the Modbus protocols, is

unbalanced, single ended, and usually uses parallel wiring.

Because of this, transmission using RS232 tends to be slower (20Kb/sec)

and is limited in distances of 50 feet. On the other hand, RS485

is both balanced (120 ohms) and uses differential mode allowing for

transmission speeds of up to 10Mb/sec. and distances of up to 4000 feet.

It also uses twisted pair cables to prevent electrical noise, in addition

to line drivers which resolves ground level differences and impedance

mismatches. Modbus RTU (Remote Terminal Unit) uses RS485 for this

reason. The chart below details the differences between the two

standards.

Modbus RTU Format

Slave ID

The first byte in the string is the slave address, or device address.

Each device in the network is assigned a unique address from 1 to 247.

However, Modbus TCP/IP (Ethernet) with allow for greater device addresses.

Function Code or Protocol Data Unit (PDU)

The next byte in the data string is the Function Code, or Protocol Data

Unit. It tells the device how to respond.

-

0x01 (01)

- Read from table Discrete

Output Coils

-

0x02 (02)

- Read from table Discrete

Input Contacts

-

0x03 (03)

- Read from table Analog

Output Holding Registers

-

0x04 (04)

- Read from table Analog

Input Registers

-

0x05 (05)

- Write once to table Discrete

Output Coil

-

0x06 (06)

- Write once to table Analog

Output Holding Register

-

0x07 (07)

- Diagnostics - Read Exception Status

-

0x08 (08)

- Diagnostic

-

0x0B (11)

- Diagnostic - Get Com Event Counter

-

0x0C (12)

- Diagnostic - Get Com Event Log

-

0x0F (15)

- Write multiple times to table Discrete

Output Coils

-

0x10 (16)

- Write multiple times to table Analog

Output Holding Registers

-

0x11 (17)

- Diagnostics - Report Slave ID

-

0x14 (20)

- File Record Access - Read File Record

-

0x15 (21)

- File Record Access - Write File Record

-

0x16 (22)

- Mask Write Register in table Analog

Output Holding Registers

-

0x17 (23)

- Read/write multiple times to table Analog

Output Holding Registers

-

0x18 (24)

- Read FIFO Queue in table Analog

Output Holding Registers

-

0x2B (43)

- Diagnostics - Read Device Identification

Address

The next two bytes are the device output address, different from the Slave

ID.

Data

The next 2 bytes is the command (1 byte), followed by a delay (1 byte).

CRC (Cyclic Redundancy Check)

The last 2 bytes are for the CRC checksum value.

CRC Algorithm (in C#)

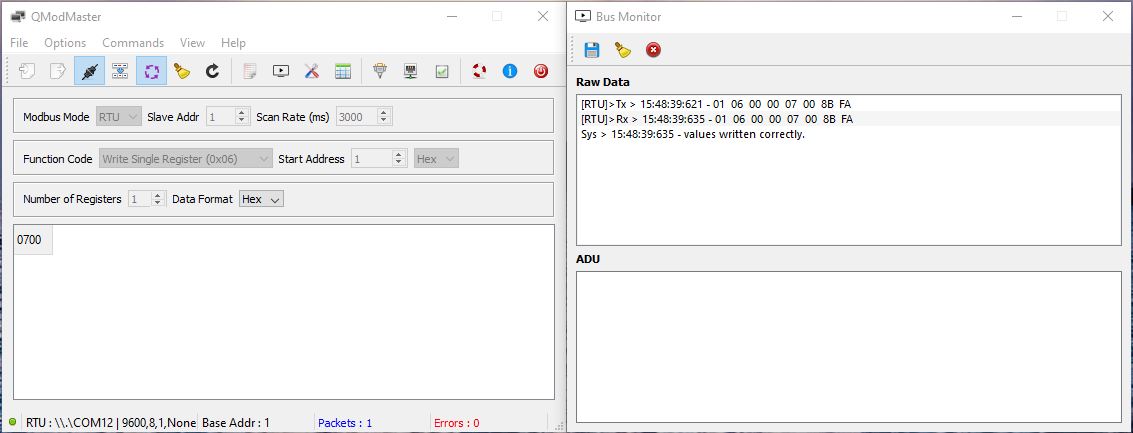

QModMaster

QModMaster is a free Qt based implementation of a Modbus master application.

It has a source code and libraries which allows the programmer to develop

Modbus interfaces. Qt is a

free open source Integrated Development Environment (IDE) which allows users

to develop software in multiple languages (C++, C#, Python, Javascript,

etc.) which could be compiled in multiple platforms (Windows, Linux, macOS,

Android, etc.). Programmers can convert seamlessly between operating

systems without changing source code.

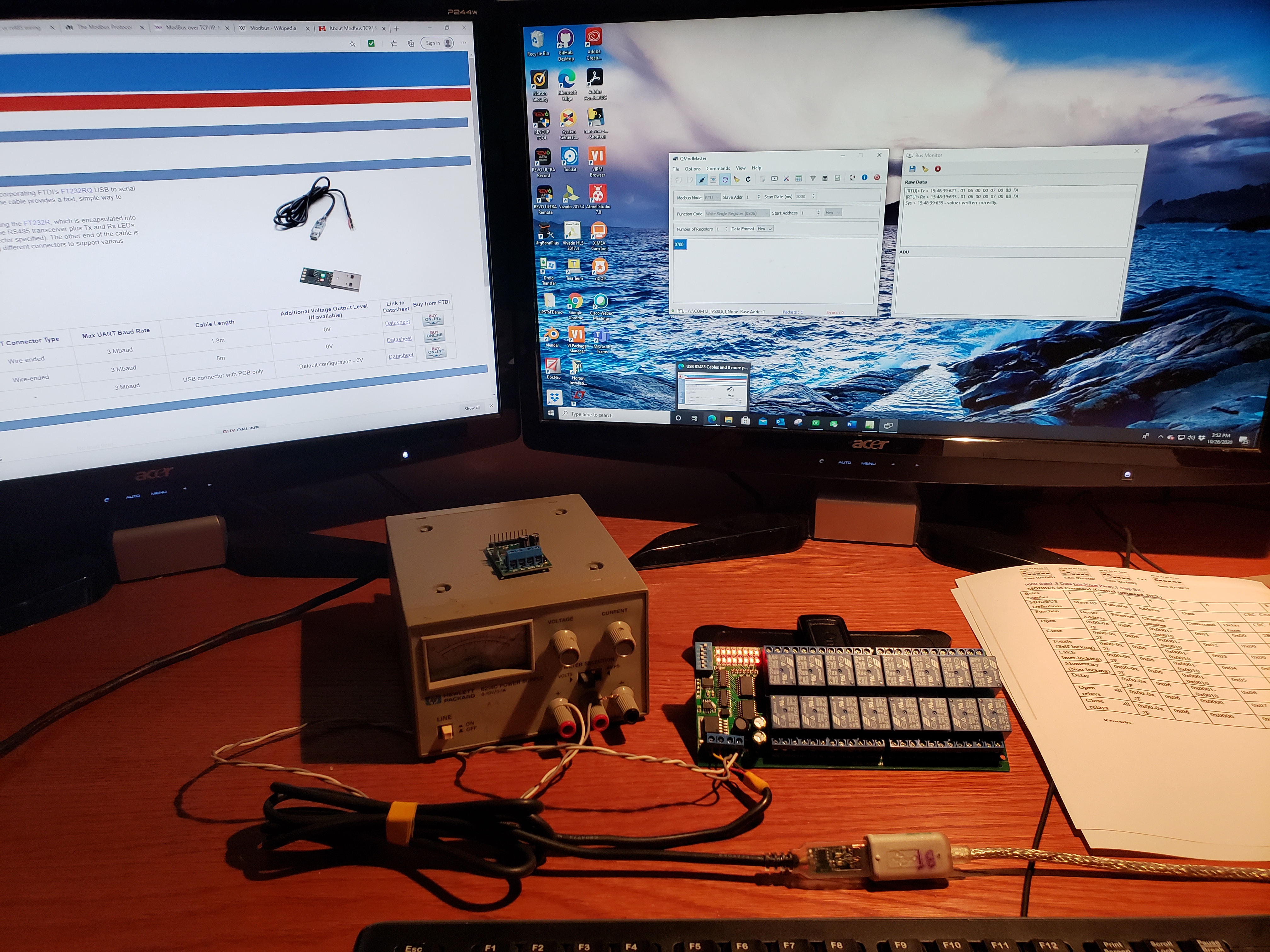

Below is a simple demonstration of Modbus RTU developed using Qt and

qModMaster. I went with Modbus RTU because the converters and devices

are cheaper than Modbus TCP/IP stuff. I am using a virtual comport

using a serial UART converter based off of FTDI's chip set

FT232R. It converts the USB port to RS485 needed for Modbus.

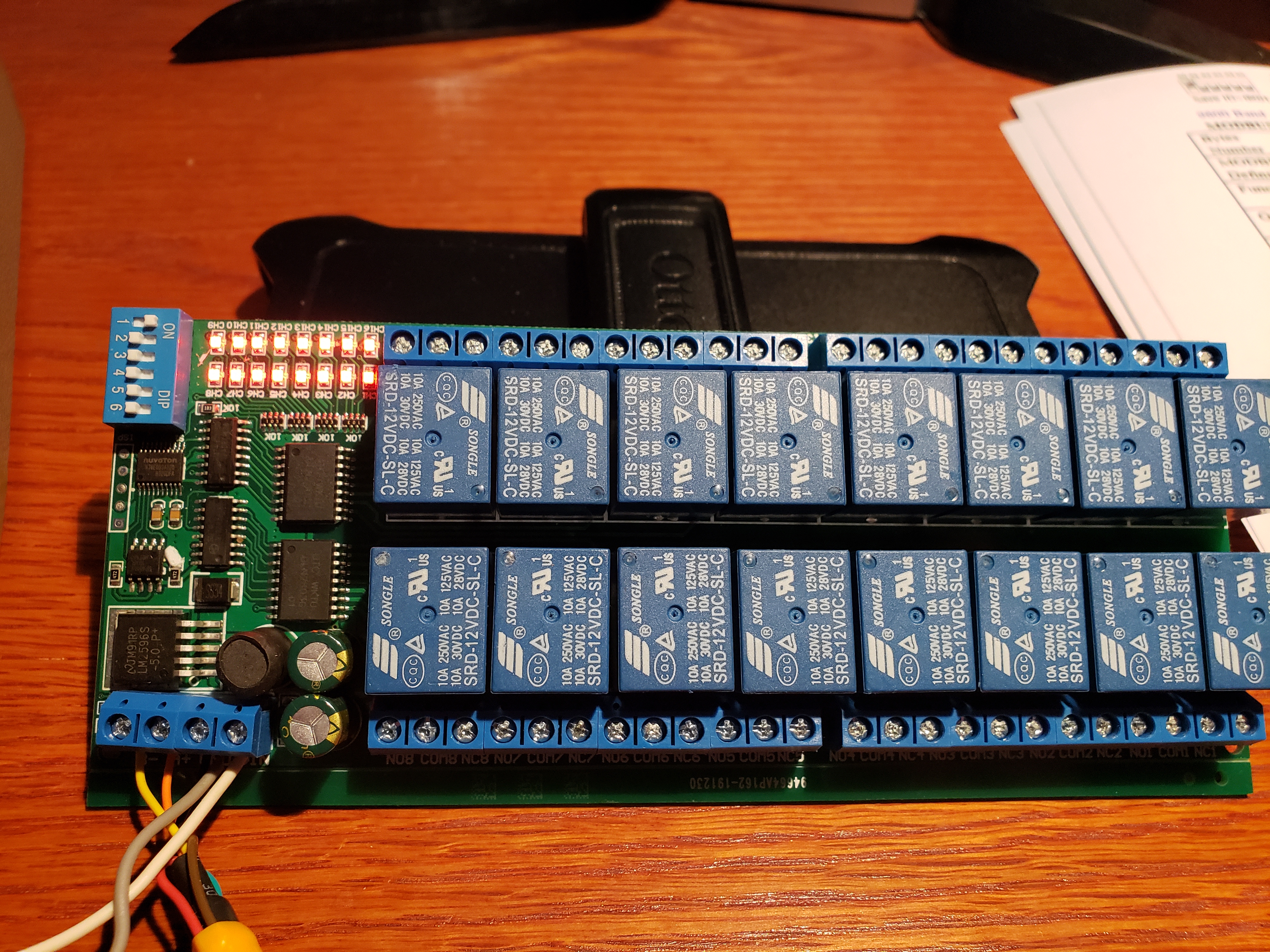

The device, or slave, is a R421B16 (16 Channel RS485 Relay board). It

uses a standard 3 wire Modbus connection (A+, B-, Ground), with an external 12V

supply. A simple test, establish a connection using the virtual comm

port (COM12), and send a string to open all the relays. When I get 10

minutes I'll write a program to sequence the output ports.

Just a note, download the code and build the utility yourself. There

appears to be an error with the pre-built which was online, or at least the

version I was using.

Source:

The Modbus Protocol In-Depth (National Instruments)